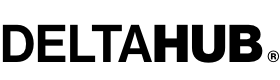

Problem

The Traditional Roadblock

In typical manufacturing, product design can drag on for months or even years. Once expensive molds are made, adapting or fixing flaws becomes a massive undertaking—leading to wasted resources and stagnant innovation.

1. Rigid and slow

Traditional production demands complex molds and lengthy lead times. Minor changes require entirely new tooling, stalling any quick improvements and driving costs sky-high.

2. Excessive stock

To justify mold expenses, companies often mass-produce huge inventories upfront. If the product misses the mark, warehouses fill up with unsold items—adding storage fees and environmental impact.

3. Lack of personalization

Because traditional tooling is costly, companies rarely offer variations. Customers are forced into one-size-fits-all solutions, stifling true innovation and tailored experiences.

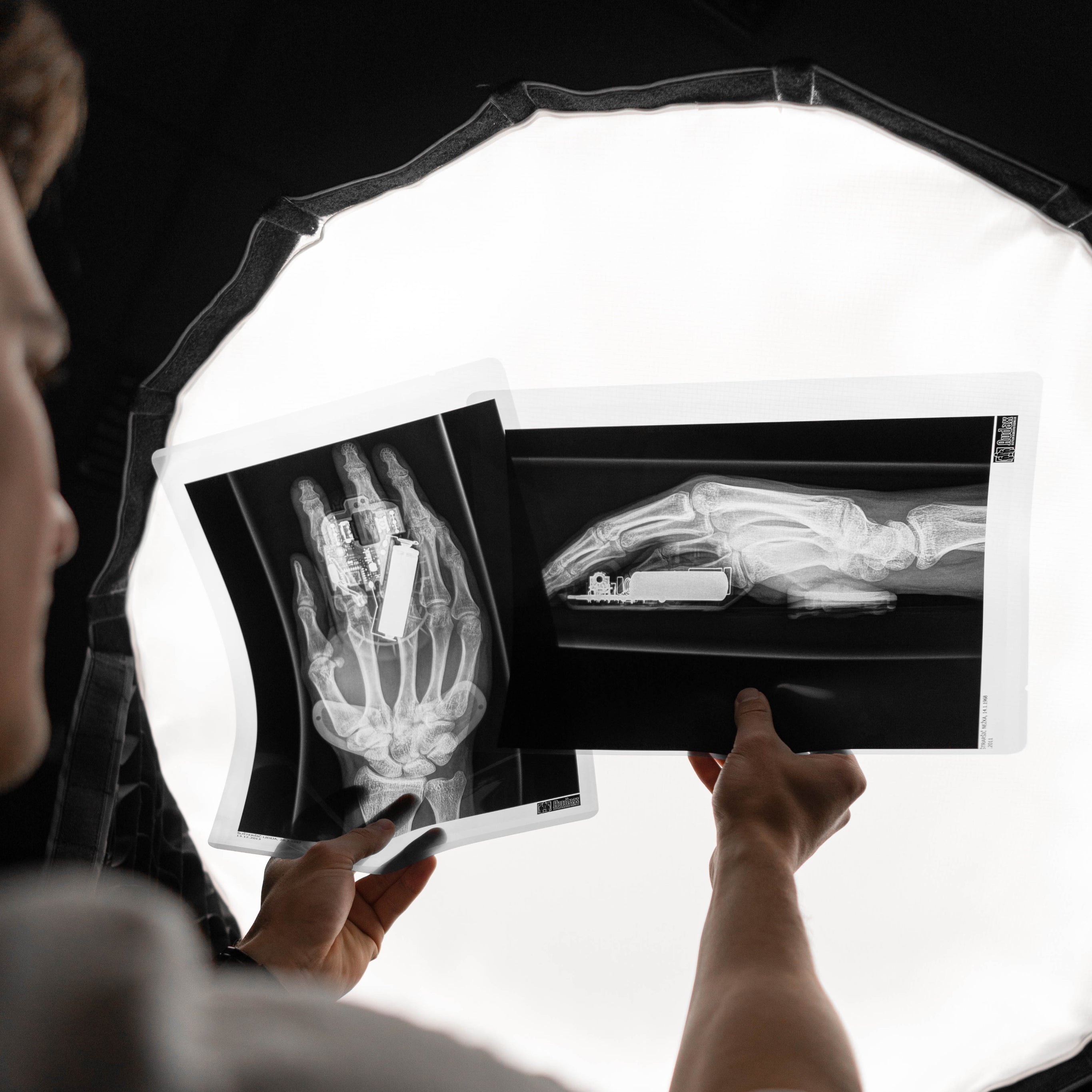

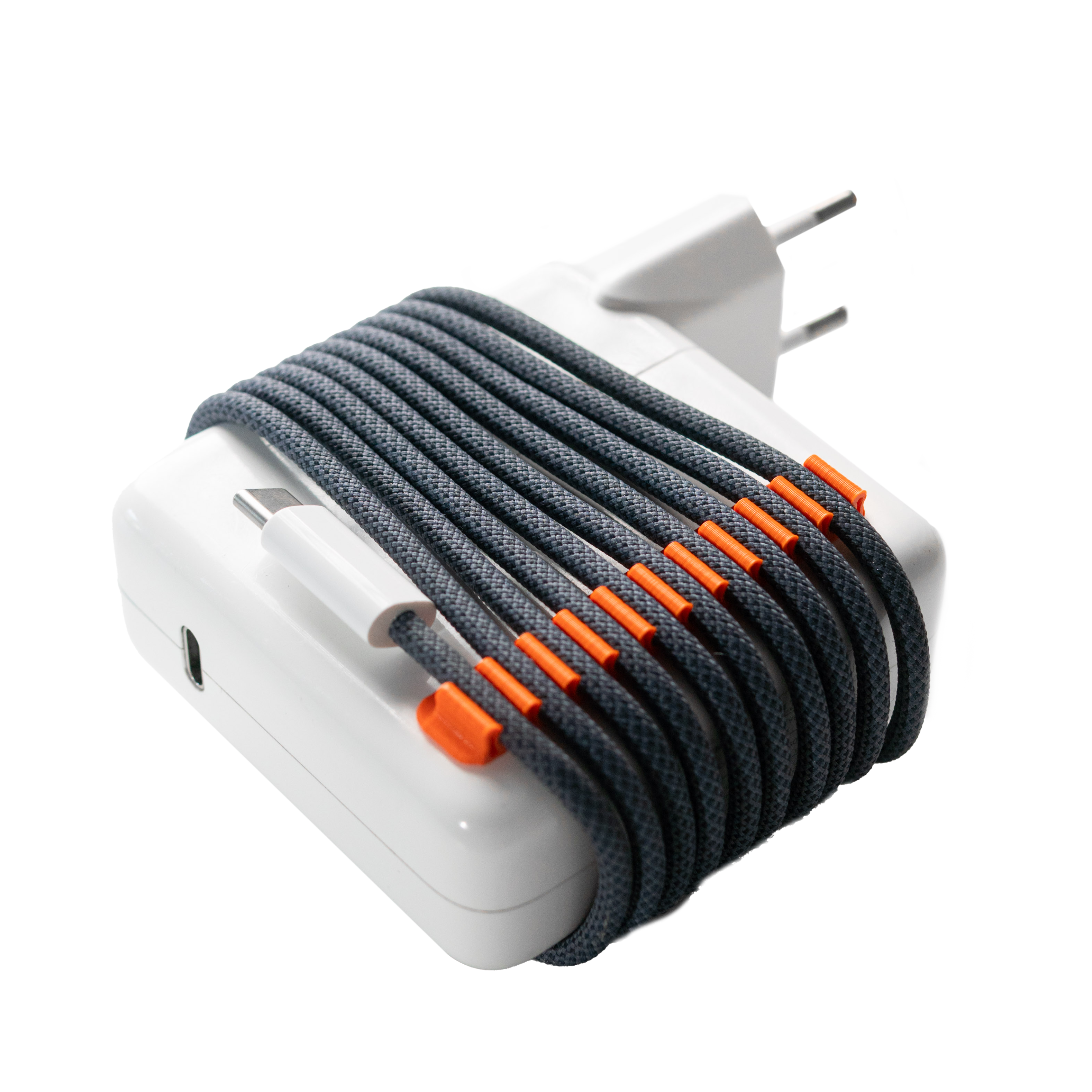

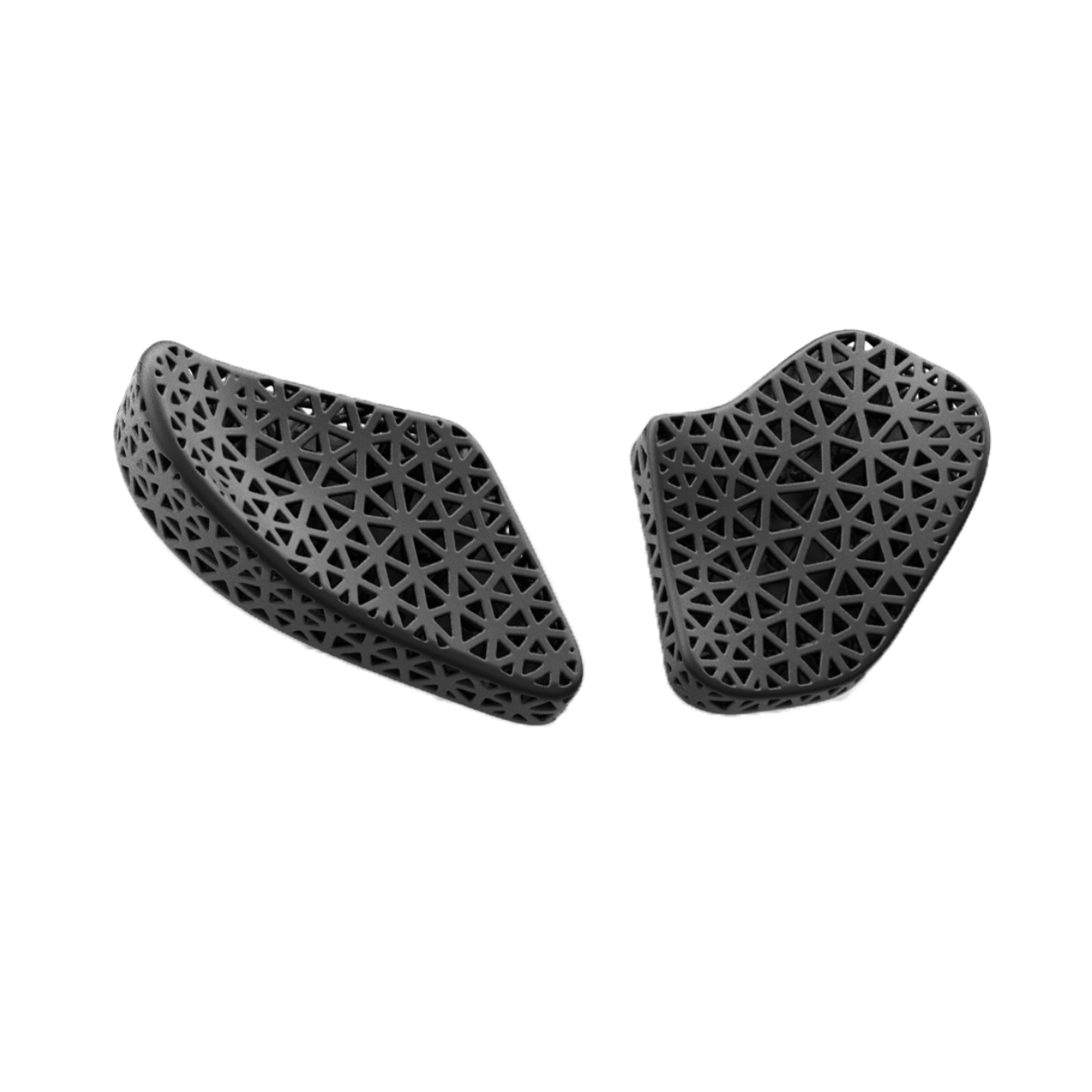

We’re on a mission to cut waste and boost creativity. While some products remain mass-produced, we’re shifting toward local, on-demand 3D printing for future releases.

By printing only what’s needed, we can adapt designs faster, avoid surplus stock, and shrink our carbon footprint—helping build a more sustainable, agile tomorrow.

We’re on a mission to cut waste and boost creativity. While some products remain mass-produced, we’re shifting toward local, on-demand 3D printing for future releases.

By printing only what’s needed, we can adapt designs faster, avoid surplus stock, and shrink our carbon footprint—helping build a more sustainable, agile tomorrow.

Our on-demand approach inherently cuts down on waste, minimizing surplus inventory and the resources used to maintain it. We see ourselves as part of a global movement that respects materials, energy, and people’s needs—manufacturing just enough, just in time.

Our on-demand approach inherently cuts down on waste, minimizing surplus inventory and the resources used to maintain it. We see ourselves as part of a global movement that respects materials, energy, and people’s needs—manufacturing just enough, just in time.

Shape the Future of Everyday Essentials

We believe that the best ideas often come from individuals who see an everyday challenge and think, “I can fix that.” If you’re an independent designer, inventor, or creative studio with a concept you’d like to bring to life, Deltahub welcomes you.

Why Join Our Network?

Agile Prototyping: We use local 3D print hubs for quick test batches, so you can iterate faster and more affordably.

Revenue-Sharing Model: Designers earn a fair percentage of every product sold—no complicated licensing.

Global Reach, Local Impact: Your design is printed wherever your customers are, minimizing shipping and waste.

Sign up